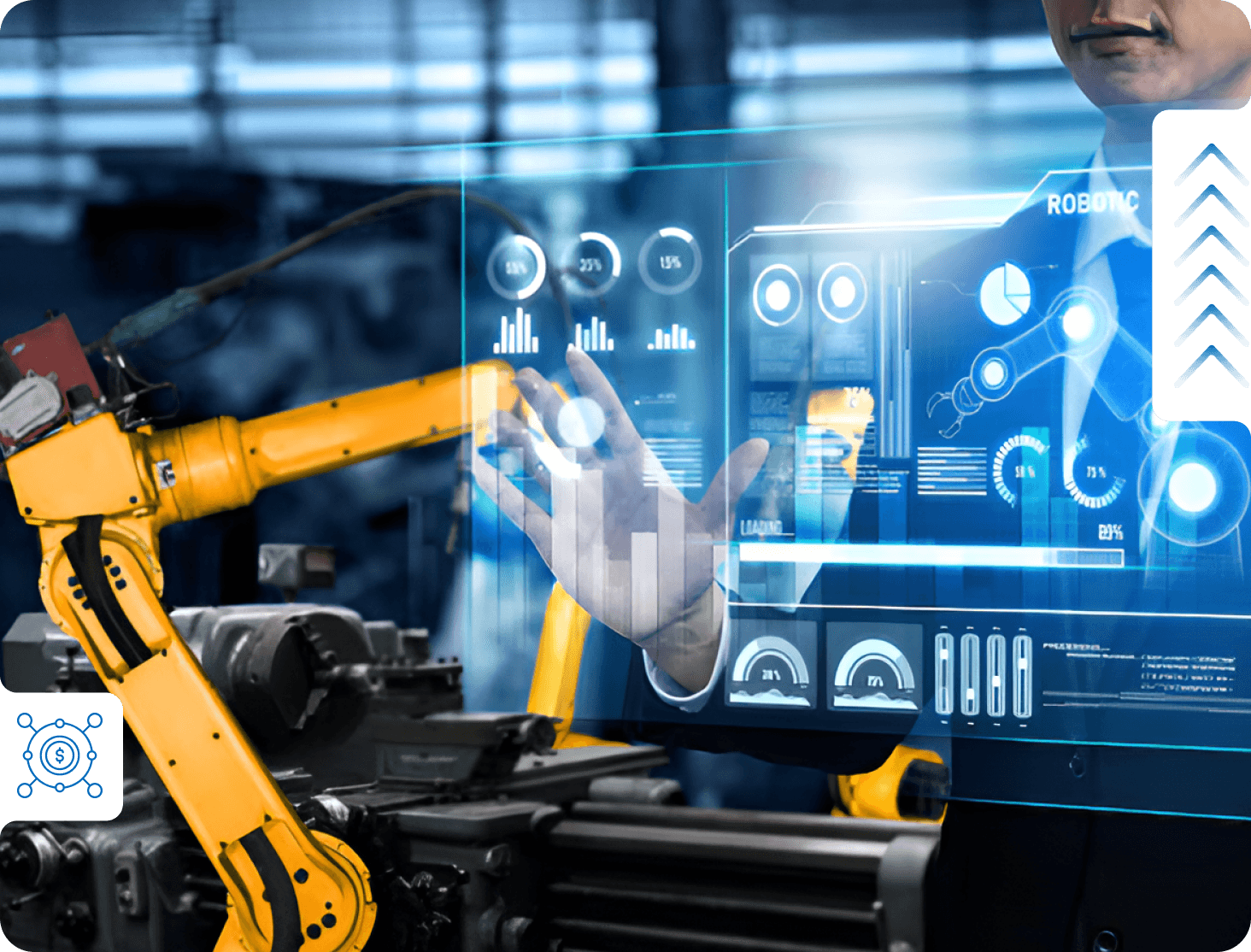

In a high-reliability, high-speed, precision economy, the manufacturing sector is changing rapidly. From shop floors of manufacturing to global supply chains, digitalization and intelligent automation are no longer an option but strategic imperatives.

We at Convertec enable manufacturing businesses to transform their manufacturing, maintenance, and quality control systems through custom-built technologies. You might be constructing intelligent factories, automating regulations, or embedding AI in predictive maintenance processes—whatever it is, we give you the architecture and delivery you require to achieve operational excellence.

Manufacturing is complicated. It is a dynamic balance between quality, uptime, resource utilization, and safety—under cost and regulatory constraints. These underlying issues overwhelm the industry:

Legacy Systems Hindering Progress: Legacy SCADA systems, manual tracking, or siloed processes that impede and make digital transformation uneven continue to exist in most facilities.

Lack of Real-time Visibility:Poor visibility of real-time performance information or equipment diagnostics leads to reactive, not proactive, decision-making.

Compliance Burden:Environmental, worker safety, and quality control regulations demand accurate and auto-mated audit trails.

Downtime and Maintenance Costs: Downtime resulting from equipment failure or maximizing utilization without advanced analytics is practically impossible, resulting in unexpected downtimes and high repair costs.

Isolated Workflows:If factory software does not exchange data with ERPs, CRMs, or IoT devices, it leads to departmental siloing.

We address these hurdles head-on by delivering integrated, future-ready solutions that align with your manufacturing goals.

Convertec enables industrial businesses to automate, modernize, and simplify at every level of business. Our efforts are focused on real results:

Interface and digitalize current production systems with modern API layers and IoT gateways

Facilitate predictive maintenance through real-time sensor input and AI-driven analytics

Automation of repetitive and mission-critical procedures to remove human mistake and improve throughput

Create floor manager and technician mobile-first inspection and audit software

Make SCADA, MES, and ERP user interfaces more user-friendly and faster in decision-making

Adhere to traceable, reportable electronic records and regulation-mandated verifications

Create dashboards that aggregate data from across lines, plants, and systems to be tracked centrally

Our goal is to ensure that every layer of your manufacturing stack works smarter, not harder.

We design automated workflows for everything from production planning to part inspection and compliance reports. They cut down on delays and standardize procedures between departments and sites..

With edge computing, AI, and IoT solutions, we create predictive maintenance platforms that track wear-and-tear metrics, optimize asset utilization, and reduce unplanned downtime. Your equipment is now smarter—and more reliable.

We develop extremely reliable mobile apps for site managers, quality inspectors, and maintenance staff. The apps operate offline, sync in real time, and are customized by every user role—ensuring real-world functionality where networks are weak.

We help manufacturers transition away from inflexible legacy systems towards microservices-based, containerized, and future-proof UIs. SCADA, MES, or home-grown ERP, we reimagine it for the cloud and the future.

Our solutions integrate machine telemetry, factory data, and operational KPIs into actionable dashboards. Executives and plant managers have a single pane of glass through which to see performance, alert on problems, and respond in real-time.

Convertec's approach to delivering change is not patchwork fixes—it's end-to-end innovation. That's what our customers receive:

20–40% decrease in equipment downtime through predictive maintenance

30% increase in production efficiency through automation of workflow.

Simplified compliance audits through centralized, electronic reporting

Reduced total cost of ownership by consolidating system and data silos

We bring measurable value to operations, IT, compliance, and the bottom line.

Industry-deployable tech stacks that are compatible with PLCs, IoT gateways, MES systems, and ERP tools

Discrete and process manufacturing experience working in the automotive and aerospace, consumer goods, and food processing industries

Robust security measures for protecting production data and access on networked equipment

Flexible delivery practice that accommodates pilot-first practices, quick iterations, and phased rollouts

Cloud-native and on-premises support, which gives you flexibility for your specific infrastructure

We don’t just deliver software—we create digital ecosystems that power your industrial future.

We understand today's manufacturing DNA. Our cross-functional organizations combine industrial domain expertise with wide technology experience to deliver tangible, measurable impact. That's why we're different:

In an economy requiring production lines to process as fast as the boardroom, manufacturing innovation starts with smart software and networked systems. From beginning your Industry 4.0 on a pilot basis to digital capability growth in multiple plants, Convertec helps you build, automate, and optimize. Ready to make every machine, system, and process count? Let’s engineer your digital advantage.

Yes. We specialize in layering modern interfaces and APIs over legacy industrial systems — enabling real-time visibility, interoperability, and smoother transitions to cloud or hybrid models.

Absolutely. Our solutions combine sensor data, edge processing, and AI analytics to predict failures, optimize uptime, and enable condition-based maintenance across your entire asset fleet.

Our mobile and edge applications are built for field reliability. They operate offline, cache data locally, and sync automatically — ensuring continuity even in network-restricted facilities.

Yes. Every solution includes built-in digital records, audit trails, and validation layers to meet industry-specific regulatory requirements — from quality assurance to safety protocols and environmental controls.